In situ testing

SCPTU rig

Designing

Technologies

Microblasting

Dynamic replacement

Jet Grouting

Pipe roofing

Vibro-Replacement and Grouted stone columns (VSS)

Vibroflotation

Continuous Fh3ght Auger (CFA) piles

Soil displacement piles

Deep Soil Mixing (DSM)

Slurry walls

Our offer

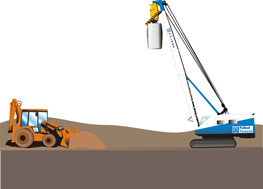

The dynamic replacement method

The dynamic replacement method is used for soft subsoil improvement. The best results are obtained for shallow soft soil layers up to 5.0-6.0 m of thickness.

It is applicable to almost every type of soil, however, it is especially efficient for:- organic soils

- saturated fine-grained soils

- man-made soils (rubble, waste etc.).

Within the dynamic replacement method columns of a coarse material are formed dynamically with a specially shaped tamper.

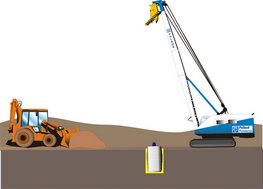

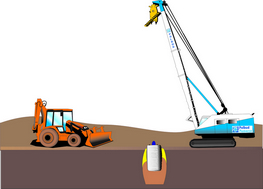

A tamper of 8-12 tons in weight is dropped from a height of 10-15 m onto the surface where the column is formed. The depressions obtained after tamping are successively filled with a coarse material like sand, gravel, stones, slag, rock or concrete rubble. The procedure is continued until the appropriate consolidation level is reached, which is controlled by measuring the penetration of the tamper per blow. The depressions are normally refilled with a coarse material twice or three times during formation of a single column. The tampering action causes a lateral expansion of the column and its diameter is much higher than this of tamper.

Results

As a result, a system of compacted columns with a high axial bearing capacities is obtained. The diameter of a single column may range between 1.2 m and 3 m. Lateral expansion of the columns improves also the surrounding soft soils. An additional important issue is the induction of a high excess pore water pressure in the soil between the columns during tampering. The presence of the highly permeable columns allows a fast drainage and dissipation of the induced excess pore water pressure. The consolidation time of the improved soft soil deposit is significantly reduced. The technology simply joins the standard dynamic compaction methods with the soft soil improvement.

Advantages of the method:

- simple operation,

- efficiency,

- the costs are considerably lower when compared to the classical soil replacement and many other technologies of soft soil improvement,

- due to the fact that it is not necessary to use precompression embankments, the whole operation is completed in a short time.

- it improves the mechanical characteristics of the surrounding subsoil (unlike precast concrete piles or drilled piles).