In situ testing

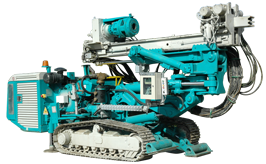

SCPTU rig

Designing

Technologies

Microblasting

Dynamic replacement

Jet Grouting

Pipe roofing

Vibro-Replacement and Grouted stone columns (VSS)

Vibroflotation

Continuous Fh3ght Auger (CFA) piles

Soil displacement piles

Deep Soil Mixing (DSM)

Slurry walls

Our offer

- soil improvement under road or railway embankments, airfields and bridgeheads;

- deep foundations;

- strengthening of existing foundations;

- soil retaining structures;

- slope stabilization;

- tunnel linings;

- leakproof excavation walls with deep bottom-sealing slabs;

- erosion protection of the bridge pillars foundations;

- leakproof barriers in the underground structures.

Soil improvement by jet grouting technology is possible in most kinds of soils, from soft clays and silts to loose sands and gravels.

Technology

The jet grouting method consists in cutting and mixing phases of the soil with the cement binder which jets from the nozzles under a high pressure. The process starts with drilling a hole with a rod. Then the rod is being pulled back and rotated while the binder is jetted through the nozzles. It breaks up the soil structure completely and performs a deep soil mixing to create a homogeneous impermeable material after the hardening process.

Apart from columns and walls it is possible to construct more complex modules like barriers, slabs or platforms. These elements may be formed in various shapes, geometries and positions depending on the designer’s specifications. It is also possible to reinforce the jet-grouting columns if necessary. This is an alternative solution for other pile-technologies like CFA, Franki or precast piles.

Results:

The injected grout changes entirely the natural soil structure. The soil-grout mixture becomes a homogeneous mass with increased strength, stiffness and impermeability.

Advantages of the jet grouting technology:

- Jet grouting columns may be configured in a variety of shapes for different engineering purposes.

- The application of the jet grouting technology is feasible even in the presence of such obstacles like old foundations, stones, debris or rock rubble.

- It is the only technology (except micropiles) that might be used for strengthening old foundations.

- It is possible to improve the soil ground under airfields, squares or storing places without dismantling the pavement.

- Jet grouting columns are homogeneous and chemically stable.

- After hardening soil-grout mixtures have a high compression strength (even over 40 MPa )

- The technology is environmentally friendly and does not lead to a degradation of the subsoil or to a contamination of ground waters.

- No vibrations are induced in the soil during application, thus the technology is safe for the structures and buildings in the nearby area.

- The technology may be used in a limited space which may be inaccessible to heavy construction machinery.

- Contrary to standard injections, the jet grouting method does not induce excess pore water pressure in the soil area surrounding the formed column.

- The completion time is short in comparison with other column methods.

Polbud Pomorze offers a full scope of services associated with the application of the jet grouting technology.

A list of our applications of the jet grouting method: