In situ testing

SCPTU rig

Designing

Technologies

Microblasting

Dynamic replacement

Jet Grouting

Pipe roofing

Vibro-Replacement and Grouted stone columns (VSS)

Vibroflotation

Continuous Fh3ght Auger (CFA) piles

Soil displacement piles

Deep Soil Mixing (DSM)

Slurry walls

Our offer

The microblasting technology is used for the improvement of subsoil under civil and hydro engineering structures. It employs high-energy explosions to modify the surrounding soil. The energy generated by the explosion of 1 kg of TNT is equal to the energy of 5 tons of tamper falling free from a height of 100m. Microblasting may be applied underwater, therefore it is perfect for the harbour areas, reclaimed islands, breakwaters, etc. It is also used for soil improvement under road embankments and airfield pavements. In saturated loose granular soils the application of microblasting technology guarantees a very effective and homogeneous densification which fulfills the safety requirements for important structures like nuclear power plants or dams.

See application of microblasting:

Types of subsoil for improvement by microblasting:

- saturated loose granular soils (also offshore).

- soft fine-grained soils (peats, muds).

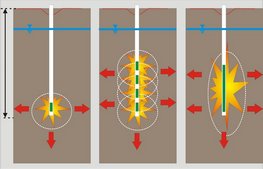

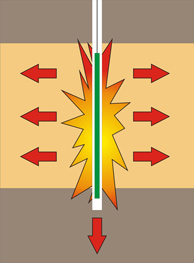

In the microblasting technology the energy is obtained from small explosive charges which are installed underground or on the ground. The mass of charges and their arrangement are carefully designed for the given ground conditions to meet expected demands.

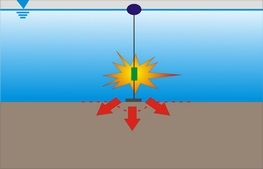

In the case of explosive compaction of underwater soil deposits, the charges are installed closely over the bottom.

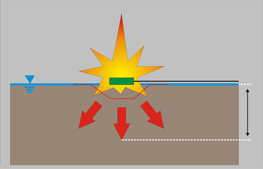

In the case of loose granular soils microblasting is applied to compact the soils. The explosion induces a high and rapid increase of excess pore water pressure. This remoulds the loose soil which subsequently settles to much denser state. Additionally, the shear waves are induced in the soil. This provides further compaction effects.

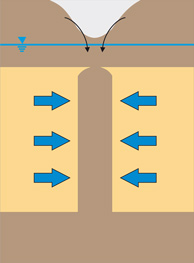

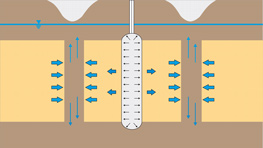

In the soft fine-grained soils microblasting is applied to improve drainage. Additionally, the partial replacement of the soft ground with sand columns is attained. The hidden charges are installed in the ground and detonated in a planned order. Before blasting an additional layer of sand fill is formed above the ground level. After blasting a stable cavity is formed in the soft ground and large excess pore pressure is generated around. In the overlaying fill the liquefaction is induced and the granular soil flows down to the cavity forming a sand pile. A characteristic depression on the sand fill surface is created. Excess pore pressure in the surrounding fine-grained soils is dissipated through the created pile which works partly as a drain as well as a supporting column. The whole operation accelerates considerably soil consolidation, which may be even twice as fast as in the case of using other technologies like geodrains, vibroflotation, standard sand piles, stone columns, etc.

The operation of microblasting technology is always followed by a continuous measurement of the settlements of the improved ground. It is very important to estimate immediate settlements just after the blasting series. Additionally, drilling is applied to control the height of sand piles. These actions ensure full control over the process.

Results

Microblasting reduces service settlements of the ground to the level requested by standards.

Safety

Polbud Pomorze follows the legal and safety regulations concerning engineering works with explosives. In the microblasting technology safety of the surrounding structures is guaranteed by careful planning and trial, monitored blasts. The microblasting method is proved to be safe to apply even at the distance of 50m from existing buildings and structures. The microblasting is not dangerous for human life or health if the operation is correctly performed, designed and controlled by experienced staff.

Advantages of the method:

Performance:- the average performance may reach 10 000 000 m3 of improved soil per month and it may be extended if necessary,

- the depth of soil to be improved is practically unlimited,

- time to attain required parameters of the improved soil after blasting is short (up to 1 month in granular soils and

- the method ensures very good strength and stiffness parameters of the ground,

- it enables continuous survey of the soil improvement quality,

- it reduces soil service settlements to the level requested by standards.

- the costs are lower when comparing to other methods of soil improvement.

- compaction of saturated loose granular soils on land and offshore,

- soft fine-grained soils improvement with sand piles formed by blasting,

- improvement of quick sands layers.

Pioneering projects

People who created Polbud – Pomorze are pioneers in the microblasting technology. They have extended the blasting methods in geotechnics for the soft ground improvement with sand piles formed by explosions. The projects listed below shows our development in applications of different blasting methods. It proves our knowledge and experience in the field.

| 1979 | North Harbour, Gdansk, Poland | Loose sands, underwater explosions. | 126.000 m3 |

| 1980 | North Harbour, Gdansk, Poland | Soft muds with loose sand layers, sand piles by hidden explosions. | 2.500.000 m3 |

| 1983/85 | Zarnowiec power plant, Poland | Loose sands, hidden explosions with elongated charges. | 1.600.000 m3 |

| 1985 | Gdynia Harbour, Poland | Loose sands, underwater explosions | 105.000 m3 |

| 1986 | Szczecin Harbour, Poland | Soft peat layers, sand piles by hidden explosions. | 280.000 m3 |

| 1988 | Sewage-treatment plant, Tczew, Poland | Soft peat and mud layers, sand piles by hidden explosions. | 510.000 m3 |

| 1989 | Breakwater, Icici, Croatia | Loose rock and gravel filling, underwater and hidden explosions. | 50.000 m3 |

A list of our field applications of the microblasting method: