In situ testing

SCPTU rig

Designing

Technologies

Microblasting

Dynamic replacement

Jet Grouting

Pipe roofing

Vibro-Replacement and Grouted stone columns (VSS)

Vibroflotation

Continuous Fh3ght Auger (CFA) piles

Soil displacement piles

Deep Soil Mixing (DSM)

Slurry walls

Our offer

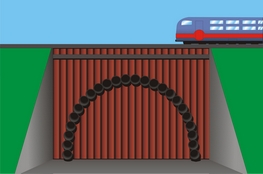

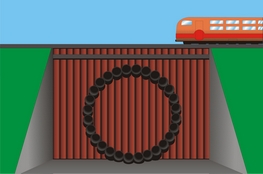

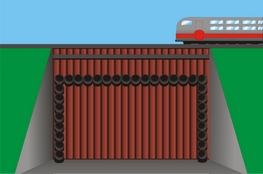

The pipe roofing system is used in building tunnels and two-level crossings with railway or road traffic embankments. It enables to maintain full traffic during the operation. The pipe-roofing system, which is also known as the umbrella method, is based on the installation of a set of parallel pipes around the contour of the tunnel.

Pipe roofing installation phases.

The construction process begins with the driving of steel pipes along the contour of the designed underground structure. The diameter of steel pipes ranges between 500 mm and 1000 mm.

The contacting pipes are connected together by steel locks. Subsequently, the pipes’ ends are closed and the pipes are filled with concrete. This forms a stable temporary shield.

In the next phase the soil under the pipe shield is excavated and additional steel frames are installed to assure a better rigidity of the tunnel support.

After finishing the steel support, the final reinforced concrete shield is formed with a bottom slab. The concrete shield is designed to carry all loading on the tunnel.

Results

A safely constructed tunnel under a road or railway embankment. The tunnel cross section may be formed arbitrary having curvilinear or polygonal shapes.

Safety

The pipe roofing technology fulfills high safety standards for the ongoing road and rail traffic and for the construction workers.

Advantages of the technology:

- pipe roofing enables to maintain full traffic (with limited speed) during the tunnelling works,

- the cross section of a tunnel may be formed arbitrarily having curvilinear or polygonal shape,

- there are no limits for length, width and height of a tunnel,

- pipe roofing may be applied in new engineering projects as well as in the case of restoration of existing underground structures,

- a closed rigid support system allows the application of the pipe roofing technology under poor ground conditions such as soft soils or high groundwater level.

Polbud – Pomorze Ltd. is one of only a few contractors worldwide offering complete works associated with the pipe roofing system, including the design. We are proud of being the first pipe roofing contractor in Poland. We have carried out the first project in the country using this technology to build a tunnel under an active railway section on an embankment (Tunnel in railway embankment in Włocławek, 2004/2005).

A list of our applications of the pipe roofing method: