In situ testing

SCPTU rig

Designing

Technologies

Microblasting

Dynamic replacement

Jet Grouting

Pipe roofing

Vibro-Replacement and Grouted stone columns (VSS)

Vibroflotation

Continuous Flight Auger (CFA) piles

Soil displacement piles

Deep Soil Mixing (DSM)

Slurry walls

Our offer

Used for shoring in deep excavations and as walls in underground structures, such as building foundations or underground garages.

Applied to all kinds of soil.

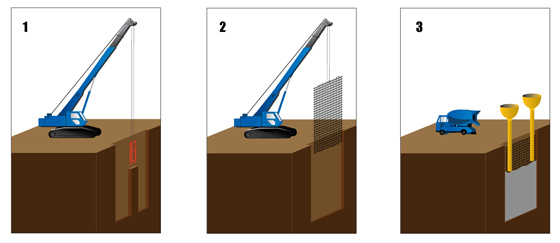

The method consists in making reinforced concrete monolithic walls in the ground. The structures are made in narrow trenches whose walls are prevented from collapsing by filling the trenches with stabilising slurry. The trenches are deepened by means of a special clamshell excavator. When the desired depth is reached reinforcement cages are introduced with separators to enable pouring concrete section by section, using one or more tremie pipes. Once the concrete fills the section the separators are removed and the process is repeated until the wall is built. At the end a reinforced capping beam is made in order to prevent possible faulting of individual wall sections. Depending on the static behaviour it might be necessary to apply strutting or anchoring of the finished slurry wall.

The result

- Slurry walls with thickness ranging from 0.6 to 1.5 m, up to 30 m long.

- Works can be carried out in close proximity to existing buildings and structures.

- Slurry walls can serve three functions at the same time, being a load-bearing component, securing excavation walls and acting as a vertical baffle.