In situ testing

SCPTU rig

Designing

Technologies

Microblasting

Dynamic replacement

Jet Grouting

Pipe roofing

Vibro-Replacement and Grouted stone columns (VSS)

Vibroflotation

Continuous Flight Auger (CFA) piles

Soil displacement piles

Deep Soil Mixing (DSM)

Slurry walls

Our offer

Used to improve non-cohesive soil by compacting vibration.

Applied to sand and gravel, and also to non-cohesive mining waste and the like.

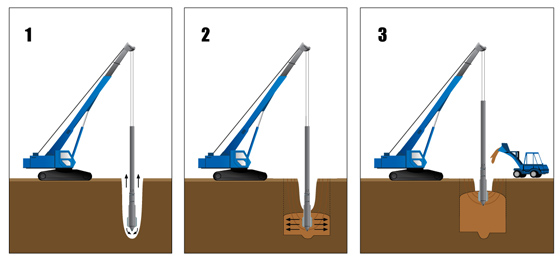

Consists in compacting the soil by means of an internal vibrator called 'vibrolance'.

In the initial phase the vibrolance is driven into the subsoil with the use of water jetting. Next, the vibrolance is pulled up in a reciprocal motion, which alters the grain size distribution, consolidates them and reduces the pore volume. As a result, the soil is compacted up to approx. 2.5 m around the vibrator. The visible indication of this is a reduced soil volume and a crater formed on the surface which is backfilled with aggregate (either original or brought in). Then the compaction process is repeated. When the compaction level improves the vibrolance begins to consume more power.

The effect

- Consolidated ground within the thickness of 3 to over 20 m.

- Increased load-bearing capacity and reduced risk of liquefaction of saturated subsoil.